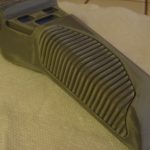

Reshaping the Grips

After the primary body work was complete, I gave the two grip sections a test fit. I noticed the upperleft grip did not sit flush against the phaser, so I dunked it in some hot water for a few seconds to soften it up. I then removed it with a towel and held it firmly on the phaser so…